Unlocking Potential: The Role of a Plastic Prototype Manufacturer in Modern Business

In the fast-paced world of business today, the need for innovation and efficient production methods has never been greater. Companies across various industries are always in search of ways to improve their product designs and reduce time to market. One invaluable partner in this endeavor is a plastic prototype manufacturer. In this comprehensive article, we will explore the significance of plastic prototype manufacturing, its processes, benefits, and how it can revolutionize your business operations.

Understanding Plastic Prototype Manufacturing

A plastic prototype manufacturer specializes in creating prototype models made from various types of plastic materials. These prototypes are critical in the product development lifecycle, allowing companies to visualize and test their designs before committing to full-scale production. This process involves several phases, including design, material selection, and production methods, which can significantly impact a product's success in the market.

The Importance of Prototyping

Prototyping is not just a phase in product development; it is an essential step that can lead to success or failure. Here are some reasons why prototyping is crucial:

- Validation of Design Concepts: Prototypes allow businesses to validate their design concepts, ensuring that they are functional and meet customer needs.

- Detection of Flaws: Identifying potential issues early in the design process can save time and resources in the long run.

- Enhanced Communication: Prototypes facilitate better communication among teams, stakeholders, and potential investors by providing a tangible representation of the product.

- Market Feedback: Gathering early feedback from users can help refine the product and ensure its market readiness.

The Process of Plastic Prototyping

The journey of creating a prototype from concept to reality involves several critical steps:

1. Concept Development

The first step involves brainstorming and conceptualizing the idea. This phase may require sketches, CAD models, and zeroing in on the expected functionality of the product.

2. Material Selection

Choosing the right material is crucial. A plastic prototype manufacturer typically works with various materials like ABS, PVC, and polycarbonate, each offering different properties that may suit the intended application.

3. Prototype Fabrication

This is where the actual manufacturing occurs. Several techniques are used in this phase:

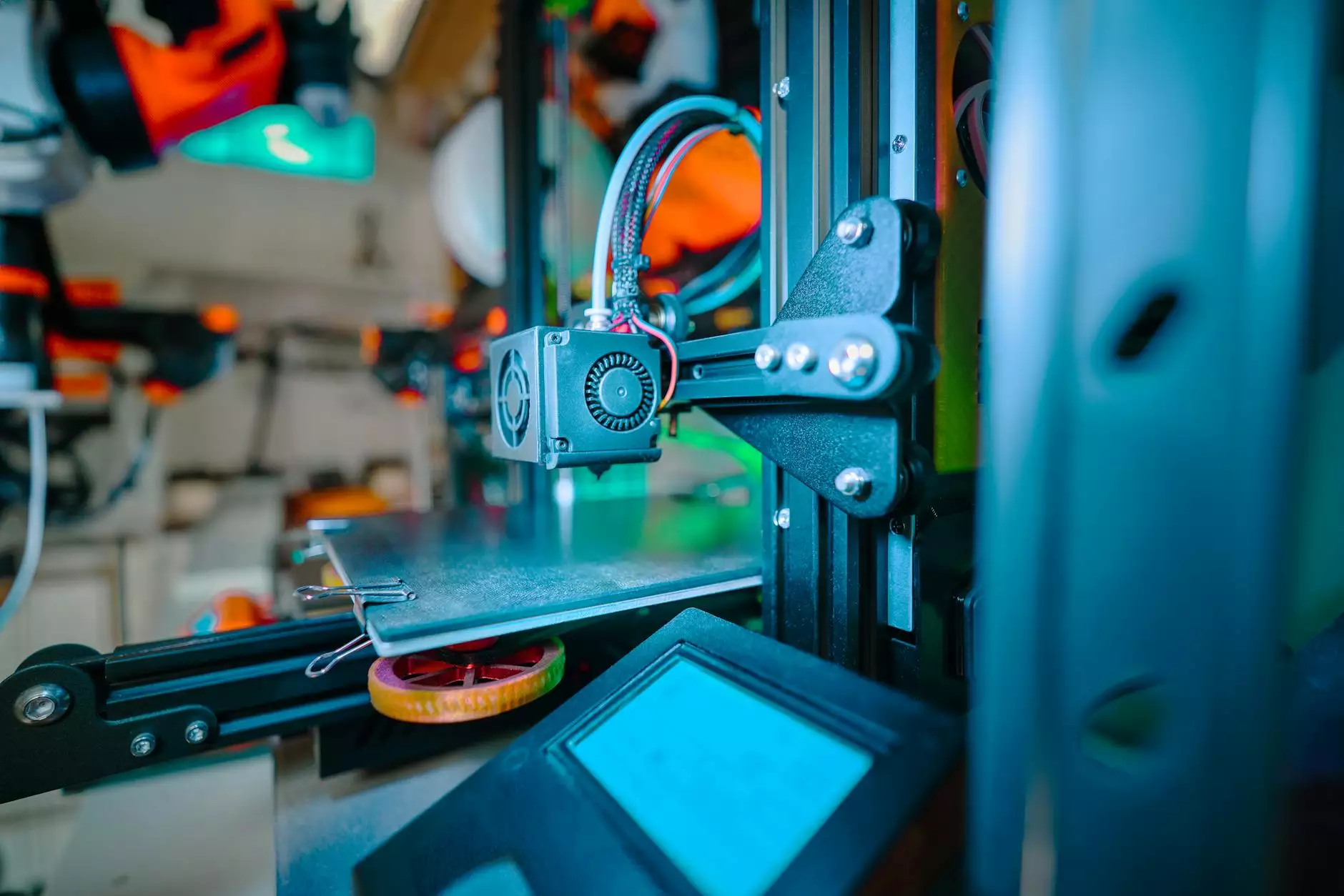

- Additive Manufacturing (3D Printing): This highly versatile method allows for intricate designs and quick turnarounds.

- Injection Molding: Ideal for high-volume production, this method creates durable prototypes by injecting molten plastic into molds.

- CNC Machining: This method provides high precision and is suitable for complex geometries.

4. Testing and Evaluation

Once the prototype is manufactured, it undergoes rigorous testing to evaluate performance, durability, and other essential features. Feedback gathered from testing will inform necessary revisions.

Benefits of Working with a Plastic Prototype Manufacturer

Partnering with a skilled plastic prototype manufacturer can provide numerous advantages:

1. Cost Efficiency

Creating a prototype can appear costly, but it often saves money by minimizing costly design errors during mass production. Investing in prototype development allows businesses to refine their products and avoid making expensive mistakes later.

2. Time-Saving

Time is of the essence in business. Fast prototyping reduces the time from concept to market, allowing companies to capitalize on new opportunities more rapidly.

3. Flexibility and Customization

Each product is unique, and a proficient manufacturer can adapt the prototyping process to meet specific requirements, ensuring that the final product aligns perfectly with your vision.

4. Enhanced Quality

By utilizing advanced technologies and materials, a credible manufacturer ensures high-quality prototypes, leading to better overall product integrity.

Conclusion: The Future of Plastic Prototyping

The role of a plastic prototype manufacturer is pivotal in the modern business landscape. As innovation accelerates and market demands evolve, the ability to produce efficient, high-quality prototypes will greatly enhance a company’s competitive edge. With the right partner, businesses can not only realize their design dreams but also navigate the complex waters of product development more smoothly.

As you consider your next big project, remember that effective prototyping is the gateway to successful product launches. A collaboration with a reputable plastic prototype manufacturer could be the key to transforming your ideas into reality.

At DeepMould.net, we are committed to providing exceptional plastic prototype manufacturing services tailored to meet your unique needs. By choosing us, you gain a partner dedicated to innovation, quality, and timely delivery. Contact us today to learn more about how we can support your next project.

© 2023 DeepMould.net - All Rights Reserved